Category

Solenoid Valve Supplier

What If Solenoid Valve Inlet and Outlet is Reversely Installed?

For a two-position direct-acting solenoid valve, it would be no affected if the inlet and outlet are reversely connected. For a two-position pilot-operated solenoid valve, it would also be not affected if the inlet and outlet are reversely installed. Due to the structural requirements of internal flow path, some solenoid valves may not establish the pilot pressure if the inlet and outlet are reversely connected, and the solenoid valves are thereof unable to work properly.

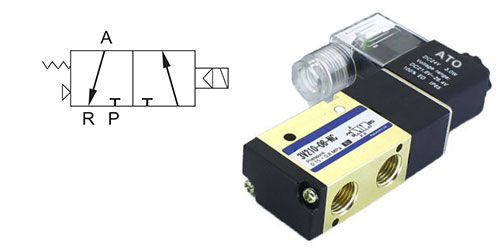

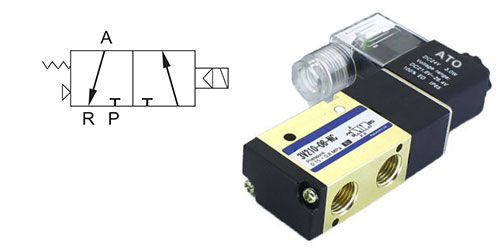

Common two-position three-way (3/2) solenoid valves and two-position five-way (5/2) solenoid valves must distinguish different interfaces, so as to match pipes accurately, otherwise, the solenoid valves would be unable to work normally.

The correct connection for the two-position three-way solenoid valve shall be as follows. The gas source is connected with the interface P (inlet) of a 3/2 solenoid valve while the interface A (outlet) is connected with the cylinder. When the solenoid valve is powered on, the compressed air from gas source moves from P to A, and then to the cylinder. When the solenoid valve is powered off, the interface P closes and the compressed air is cut off. Air in the cylinder is discharged from interface A to R.

If the 3/2-way solenoid valve is reversely connected, the compressed air of gas source will move from A to P and then to the cylinder when it’s powered on. The valve seems to be able to work. However, when it’s powered off, the situation becomes bad! Air in the cylinder can’t be discharged when the interface P is closed, and the cylinder can’t reset again. More seriously, the air source is discharged into ambient from A to R, until the gas tank is emptied and the system is paralyzed. If the diameters of solenoid valve interfaces are large, it may interfere with other gas equipment in the same gas supply pipeline. What’s more, the valve cylinder can not exhaust, which may cause process hazards in interlocking or operation.

Generally, the installation direction of solenoid valve shall be noticed when installing. The direction is marked clearly on the valve body with a label of arrow “→”, which indicates the transport direction of medium. Therefore, when installing a solenoid valve, ensure that the medium flow direction is consistent with the arrow direction on the valve body, thus avoiding the danger brought by reverse connection of the solenoid valve inlet and outlet. However, the inlet and outlet can be reversely connected in vacuum pipeline or special conditions.

Common two-position three-way (3/2) solenoid valves and two-position five-way (5/2) solenoid valves must distinguish different interfaces, so as to match pipes accurately, otherwise, the solenoid valves would be unable to work normally.

The correct connection for the two-position three-way solenoid valve shall be as follows. The gas source is connected with the interface P (inlet) of a 3/2 solenoid valve while the interface A (outlet) is connected with the cylinder. When the solenoid valve is powered on, the compressed air from gas source moves from P to A, and then to the cylinder. When the solenoid valve is powered off, the interface P closes and the compressed air is cut off. Air in the cylinder is discharged from interface A to R.

Generally, the installation direction of solenoid valve shall be noticed when installing. The direction is marked clearly on the valve body with a label of arrow “→”, which indicates the transport direction of medium. Therefore, when installing a solenoid valve, ensure that the medium flow direction is consistent with the arrow direction on the valve body, thus avoiding the danger brought by reverse connection of the solenoid valve inlet and outlet. However, the inlet and outlet can be reversely connected in vacuum pipeline or special conditions.

Post a Comment:

You may also like: